|

How stone is quarried

The first step to finding the perfect slab is finding an optimal deposit of material with desirable color, pattern, and composition.

Clearing the way to reach the best material allows a quarry to reach its full potential.

It takes lots of experience, vision and hard work to bring a quarry into full production.

After the quarry manager decides how to extract the blocks, the drilling can begin.

Once the blocks have been extracted, the journey to the processing facility can begin. |

| |

|

|

Granite countertop Installation

Before the installation, you need to strengthen the existing template by adding metal rods and plywood on top of the existing cabinetry.

To ensure that the granite Kitchen Countertop would last a long time, they should be carefully leveled.

The granite slab should be cut to its exact measurements with a diamond saw.

The seams must be perfectly sealed and the edges smoothened for a flawless finish. |

| |

|

|

Sealing natural stone

Sealing natural stone is a simple process that prevents staining and maintains stone's beauty.

The life of the sealer will depend upon the type and finish of the stone, the area of application, and its exposure to wear.

Prior to sealing, clean your natural stone thoroughly with warm water and Mira Clean. Let the stone dry, and then begin working in sections. |

| |

|

|

How stone is processing

Once blocks of stone reach the processing facility, they are cut down into smaller more manageable pieces. For tile, this means cutting the stone into billets before polishing. For slab materials, this typically means a trip to the gang saw.

After slabs are cut on the gang saw, they are moved one at a time to the polishing line, where they are laid horizontally on a large conveyer type line called a polishing line.

For stone that will be processed into tile, long strips of material experience the same polishing process, before being cut to size. |

| |

|

|

How big are slabs of stone

The size of the slabs will depend on the specific stone being considered. On average, granite slabs are 240cmup x 120cmup, although you may find some that are larger. Marble, limestone, travertine, and onyx slabs will usually be smaller. |

| |

|

|

How thick are the slabs

Natural stones are available in both 2cm and 3cm thicknesses. Consult your fabricator or contractor about which is needed for your particular project. |

| |

|

|

How much does a slab weigh

While the density of each stone and the slab size will affect the weight, 3cm granites weigh about 19 pounds per square foot, or about 900-1,200 pounds per slab. A 2cm marble will weigh approximately 600-700 pounds per slab. |

| |

|

|

Granite & granite tile cleaning

Too much cleaner or soap may leave a film and cause streaks. Use a clean rag.

The products containing acids should be avoided. The acid in high concentration etches the surface. After using the soap solution, the surface should be rinsed properly.

Do not mix bleach and ammonia; this combination creates a toxic and lethal gas.

Do not use powders or creams that may create scratches. |

| |

|

|

Granite Worktops Maintenance Guide

Granite worktops could be ideally suited for your kitchen and bathroom requirements. Granite has a polished surface which will retain its polish and color for a great many years and the only maintenance required is regular washing with clean, hot, soapy water to remove surface dirt.

Spillages such as wines, oils and acidic substances should be wiped clean immediately to prevent the possibility of staining. |

| |

|

|

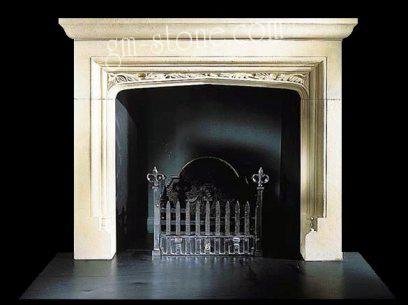

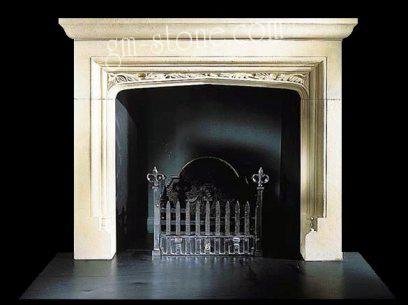

How to install fireplace facing

a. Center the backer board in front of fireplace and nail or glue it to the floor. Cut the board the same size as the hearth. Shim as necessary to ensure that it is flat.

b. Center the hearth in front of the fireplace; spread glue on the perimeter and the center. It is not necessary to completely cover with glue as the weight of the stone will help hold it in place. Be sure to position the polished side out.

c. Apply the glue to the back of the legs, and place on the wall; overlap the fireplace by approximately on each side with the polished side toward the fireplace.

d. Apply the glue to the header (polished side should face the floor) and place on the legs. Be sure the legs are even with the header. Shim side if necessary. If necessary, use roofing nails to hold stone in place while it dries. At this point be very careful as you do not want the header and legs to fall. Allow to dry following manufacturer’s adhesive instructions.

e. Install mantel. |

| |

|

|

Stone vessel sinks maintenance

To clean your sink, use a soft cloth, sponge or soapy nylon brush. Be sure to rinse the sink well after cleaning and dry. Cleaning on a regular basis will help prevent the development of hard water deposits. If you develop persistent stains, try a non-abrasive cleaner such as dishwasher soap, Soft Scrub or a professional stone cleaner solution which can be purchased from a local hardware or tile store. DO NOT use any acidic tub and tile cleaners, toilet bowl cleaners, ammonia, abrasive or soft paste cleaners, vinegar, alcohol, window cleaners or lemon juice. In addition DO NOT use abrasive cleaning pads such as steel wool, metal brushes or scouring powders. |

| |

|

|

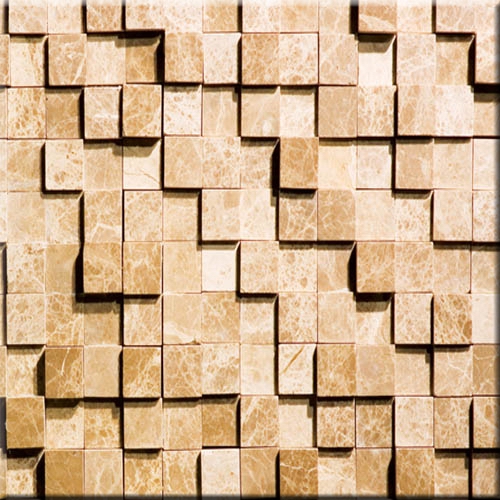

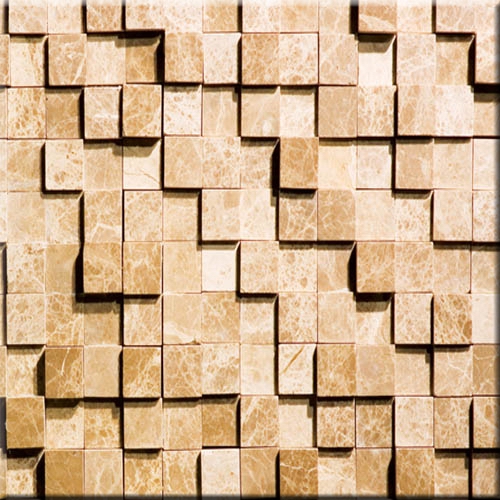

About natural stone

Natural stone is quickly becoming one of the most popular residential and commercial building materials on the market today because of its natural opulence and functional elegance.

Although it is not the least expensive option available, natural stone’s affordability is present in its durability and practicality.

The natural beauty of stone only enhances through years of use.

The choices of natural stone available to you and what you can do with them are as varied as your imagination. |

| |

|

|

General questions about natural stone

Natural stone is formed when mineral sediments are exposed to millions of years of heat and pressure. These minerals make up the variety of colors and patterns that are characteristic of natural stone. Various types of stone, in a multitude of colors and textures, are found around the world. Much of our granite comes from Brazilian, Indian, African or Chinese quarries. Marble is frequently imported from Italy, Spain and Mexico. Slate is imported from Brazil, India and China, while travertine and limestone come from Spain, Portugal, Mexico and Turkey. |

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|